Dear sirs!

Deliveries of fire-resistant and heat-insulating materials are to preliminary orders. Production of heat-insulating materials (including those of higher application temperature) as shaped articles (sectors, wedges) is possible.

PTMK-NS-250 plate

|

| Overall dimensions of plate, mm |

500*500*100 (50) |

| Temperature of application, °С |

1000 |

| Density, kg/m3 |

250±30 |

| Thermal conductivity, W/m °C, |

| at 25 ° °С |

0,047 |

| at 125 ° °С |

0,059 |

| at 300 ° °С |

0,101 |

| at 600 ° °С |

0,19 |

| |

Compressive stress at 10% linear deformation,

MPa, not less |

0.065 |

Linear shrinkage at baking temperature

more than 1000 °C after furnace lining, % |

4 ± 0.5 |

|

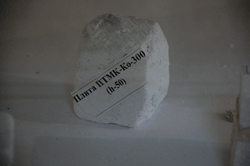

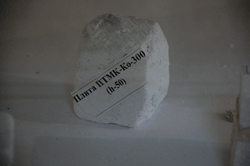

PTMK -Ko-300 plate

|

| Overall dimensions of plate, mm |

500*500*100 (50) |

| Temperature of application, °С |

1200 |

| Short-term at T, °С |

1350 |

| Density, kg/m3 |

300±50 |

| Thermal conductivity, W/m °С, |

| at 25 °С |

0.058 |

| at 300 °С |

0.12 |

Compressive stress at 10% linear deformation,

MPa, not less |

|

| 0.1 |

Linear shrinkage at baking temperature

more than 1000 oC after furnace lining, %

|

2 ± 0.5 |

|

PTMK-Ko-450 plate

|

| Overall dimensions of plate, mm |

500*500*100 (50) |

| Temperature of application, °С |

1250 |

| Short-term at T, °С |

1350 |

| Density, kg/m3 |

450±50 |

| Thermal conductivity, W/m °С, |

| at 25 °С |

0.069 |

| at 300 °С |

0.129 |

Compressive stress at 10% linear deformation,

MPa, not less |

0.1÷0.3; |

Linear shrinkage at baking temperature

more than 1000 °C after furnace lining, % |

2 ± 0.5 |

|

Firebricks

Firebricks of fibrous materials - possess properties of fibrous reinforced ceramics and heat-insulating properties. They have heightened exploiting resource, not critical to heat change-over. Mass of fibrous firebricks 9 - 10 times smaller, than of traditional ones.

|

| Overall dimensions: |

| Length, mm |

200÷1000 |

| Width, mm |

100÷1500 |

| Height, mm |

50÷250 |

Linear shrinkage at baking temperature

more than 1000 °C after furnace lining, % |

1 +± 0.3 |

| Compactness, kg/m3 |

300÷900 |

Compressive stress at 10% linear deformation,

MPa, not less |

0.1 |

| Thermal conductivity, W/m °С, |

| at 25 °С |

0.18 |

| at 125°С |

0.20 |

| at 300 °С |

0.26 |

| at 600 °С |

0.28 |

|

We bring to your attention warmly isolation high-temperature stitch material "ХПМ-Ж"

(ТУ У 6-00209775.070-99 from amendment № 1).

Heat isolation stitch material is made from mulitocrementerrestrial fibre (canvas) and impose material by a method of an insertion crementerrestrial (glass) string.

The material possesses excellent high-temperature, warmly isolation and heat-shielding properties.

To stitch a material it is applied to thermal isolation of the industrial equipment and pipelines (in quality to fibrous processing of furnaces, condensation of seams of furnaces, a high-temperature filtration, isolation of oven carriages, external isolation of furnaces, fire-prevention and other thermal barriers and screens at carrying out of thermal processing welded connections).

Characteristics:

1. Temperature of application, 0С 50 to +1150

2. Density, kg / m3 246

3. Factor of heat conductivity at 300 0С (573К), Vt/m K 0,115

4. The size, mm

- width 800 (700)

- thickness (specific pressure upon a sample 500Pa (5г/sm2) 7/15

- long 4000

5. Superficial density, kg / m 2,5/3,0

6. Explosive loading, N (kgs) 245 (25)

|

|

Cloth "ХПМ-Т, Н" = 8 mm

|

Cloth "ХПМ-Т, Н" = 15 mm

|

|

substrate - cremen a terrestrial fabric, having stitched - cremen string

|

substrate - a glass fabric, having stitched - cremen string

|

substrate a glass fabric, having stitched - a glass string

|

substrate - cremen a terrestrial fabric, having stitched - cremen string

|

substrate - a glass fabric, having stitched - cremen string

|

substrate - a glass fabric, having stitched - a glass string

|

| |

0.7m

|

0.8m

|

0.7m

|

0.8m

|

0.7m

|

0.8m

|

0.7m

|

0.8m

|

0.7m

|

0.8m

|

0.7m

|

0.8m

|

|

68.40

|

68.4

|

44.5

|

47.16

|

42.78

|

45.06

|

157.32

|

157.32

|

112.26

|

117.36

|

107.52

|

112.08

|

|

|